In an Industry 4.0 production environment, the data of the intelligent devices and machines are collected. An in-depth analysis makes it possible to make statements about the state of the devices or of the individual components, so that a predictive maintenance is possible.

This avoids unplanned downtimes and therewith optimizes customer support. Maintenance and service intervals as well as spare parts management can be better planned. Data analysis can improve the performance and life span of the equipment and increase productivity.

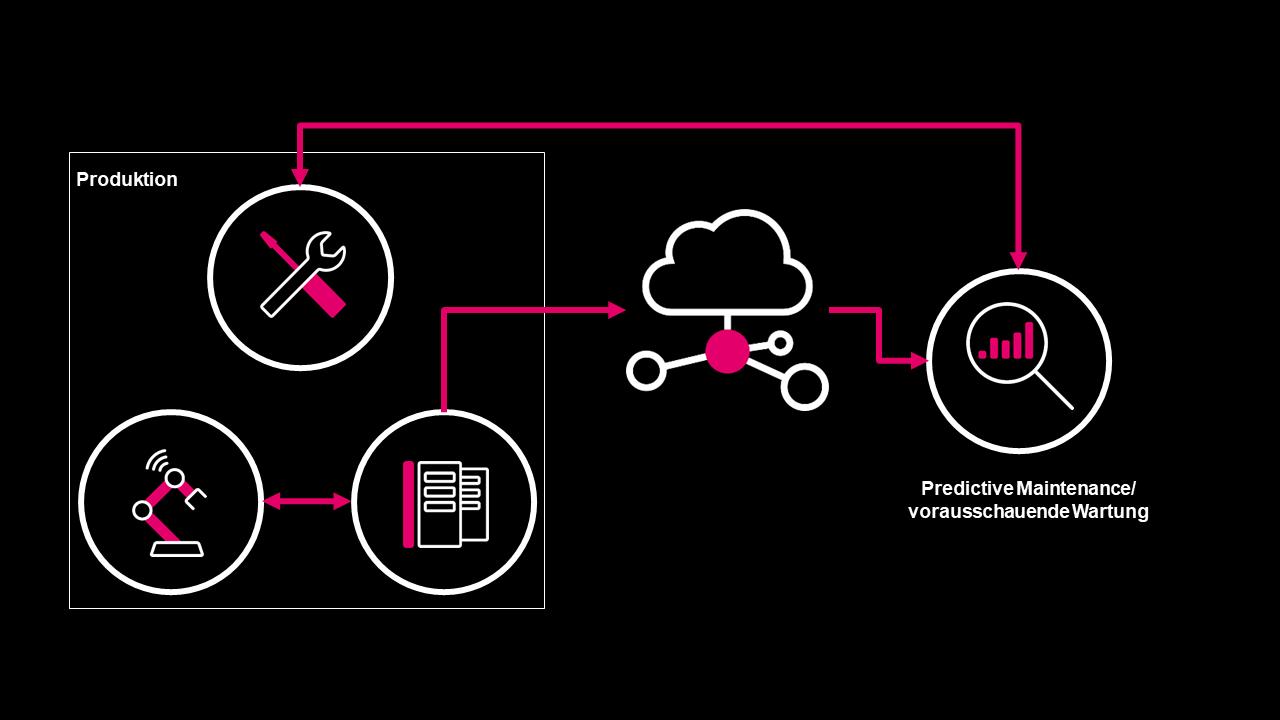

Within an Industrie 4.0 production hall, the data of all IIoT-capable devices (sensors, infrastructure, machines, robots) are collected for initial analysis and selection in an Edge Data Center. Data needed for more in-depth analysis, e.g. Industrial Analytics and Predictive Maintenance are forwarded to a Private Cloud. This can be done unidirectionally so that the sensitive, secure production environment can not be accessed from this cloud application.

Based on the analyzes / predictive maintenance, the instructions for the service personnel in the production environment are generated. The feedback after the service has been taken is in turn entered into the analysis tool to improve the predictions and thus establish a learning system.

Edge data centers are tapping into an ever-expanding market and being used in everything from industrial plant and building management, to factories and logistics centers. Efficiency and reliability are absolutely key here. Rittal’s innovative cooling units in the Blue e+ series herald a new dimension in efficiency, particularly for edge data centers in the lower output range, thanks to their integral heatpipe.

Whether Blue e+ devices are used in a data center or in an industrial environment for cooling enclosures, their flexible network connection allows all relevant data to be captured. Evaluating this data by comparing it with its digital product twin provides the basis for innovative services such as predictive maintenance.

Increase safety, reduce costs.

Manufacturing is being transformed by digitalization. Industry 4.0 is paving the way for digital twins, predictive maintenance, and smart factories.

Watch the recording of our webinar "From Edge Data Center to Predictive Maintenance" and learn about how downtimes can be reduced by up to 70% and maintenance costs by up to 30% by means of predictive maintenance.

You can choose between the Englisch or German recording.

Our experts

|

|

|

Bernd Hanstein |

Robin Reichmann |

Do you have any questions? If so, please get in touch. We’ll be only too happy to help you with any questions about Predictive Maintenance.