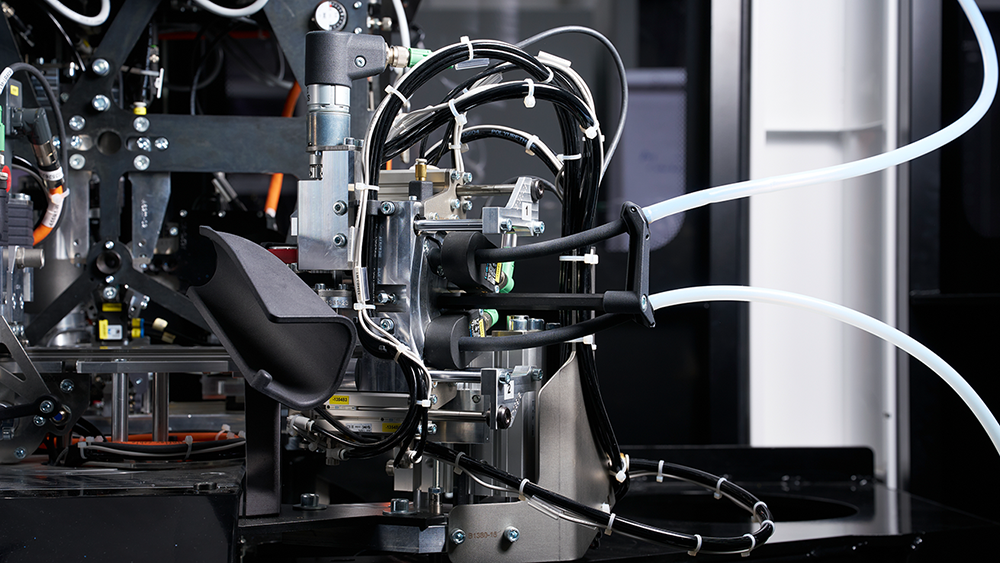

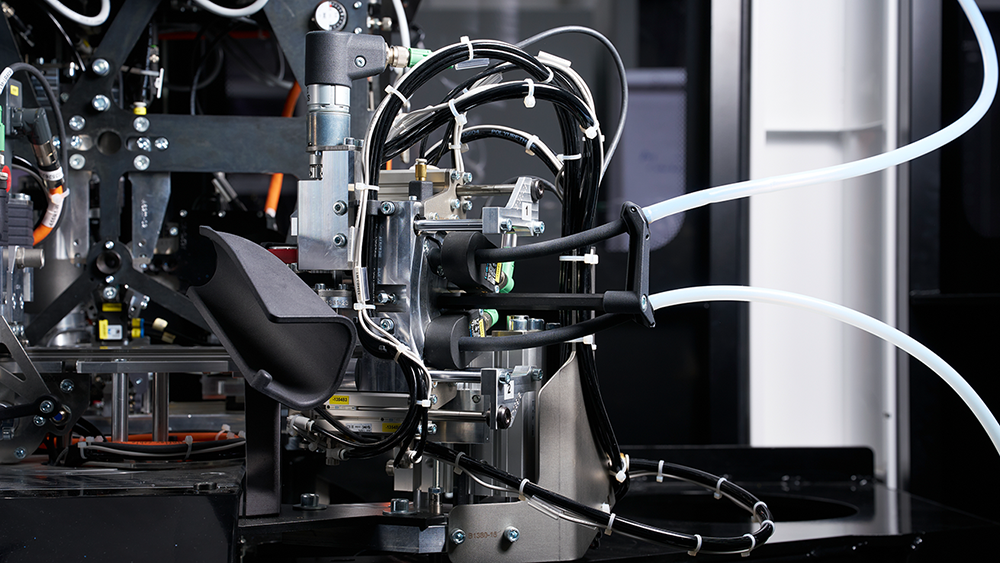

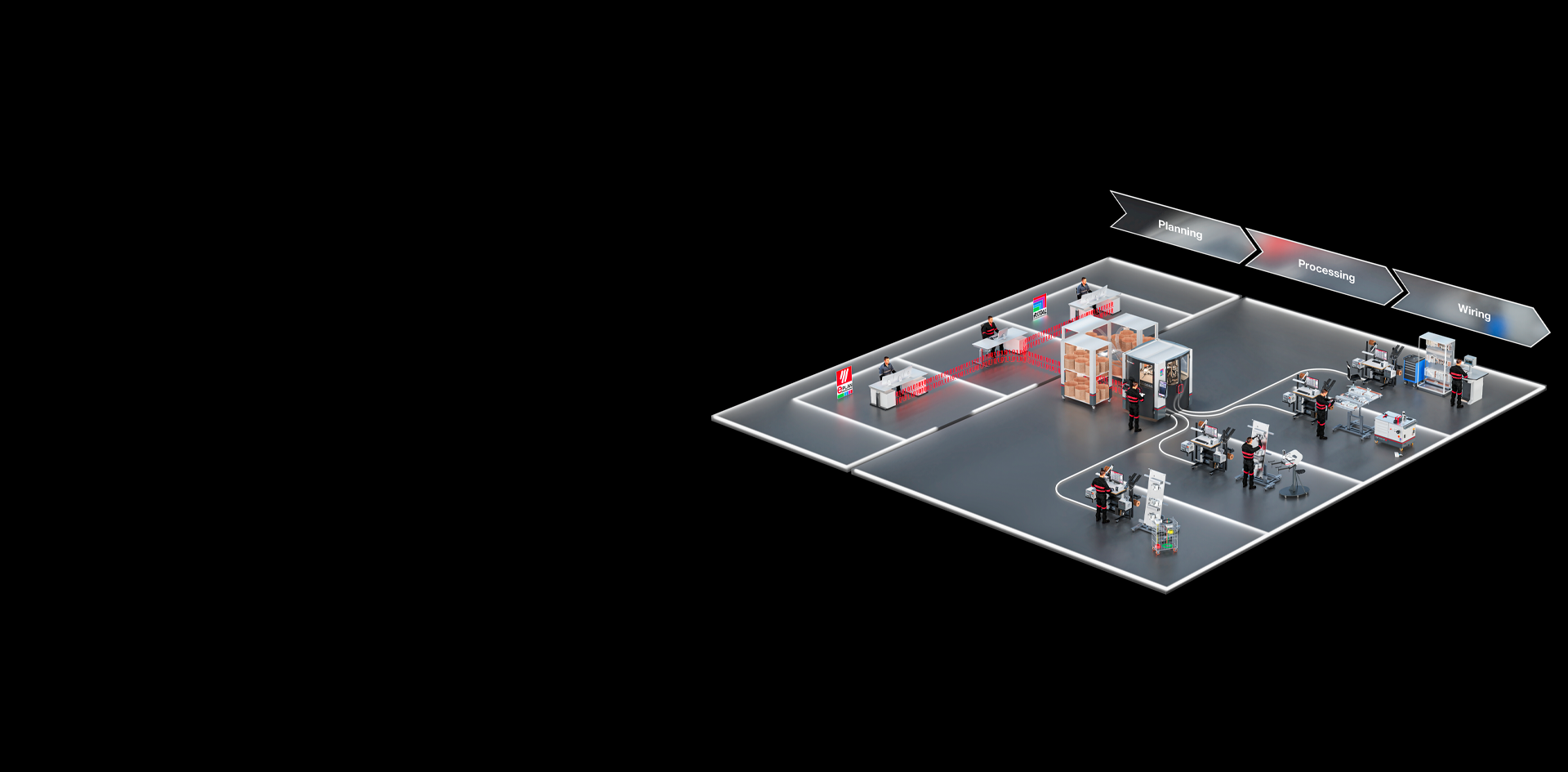

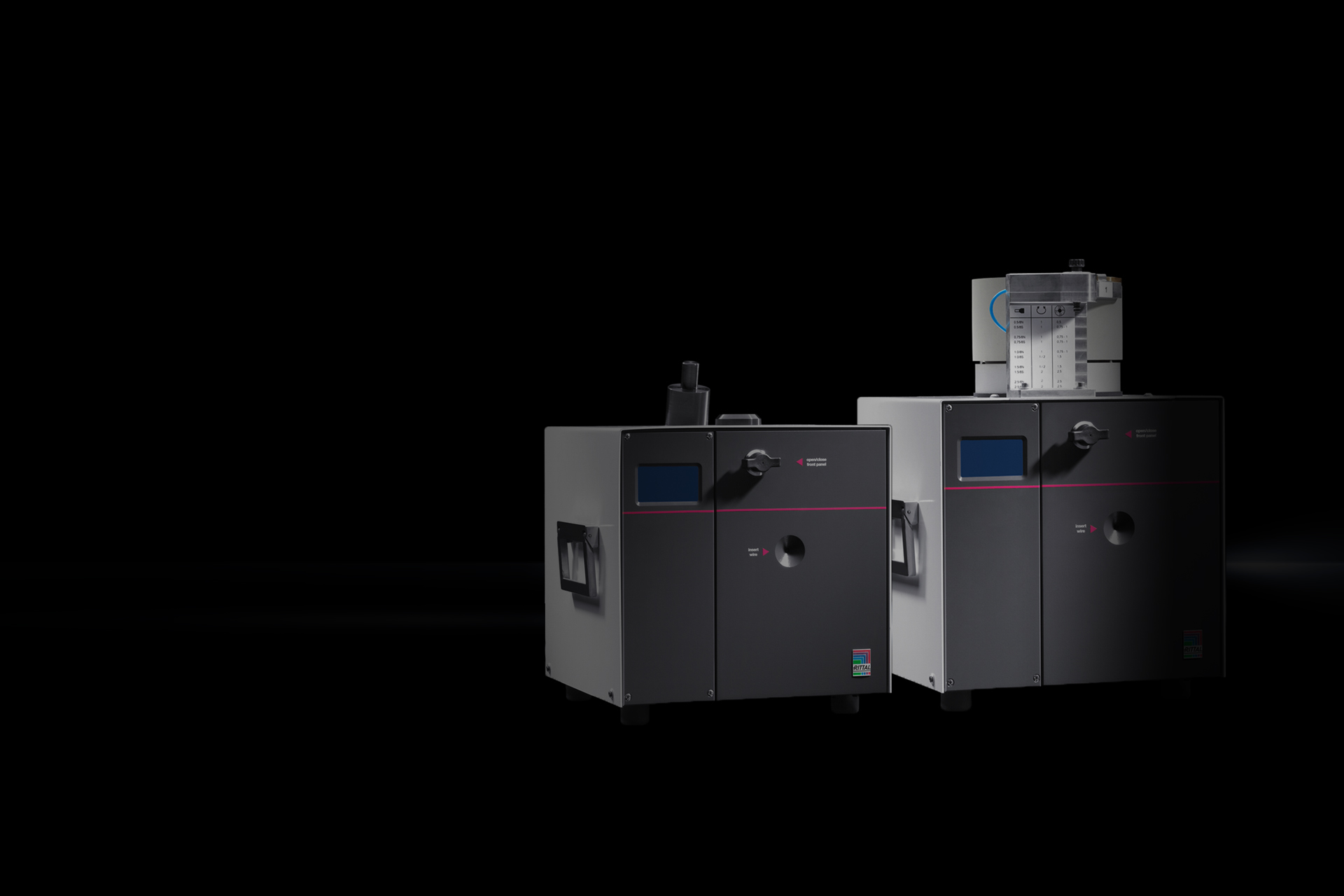

The Wire Handling System (WHS) is a fully automated wire distribution system.

Wires that have been manufactured just-in-time in the Wire Terminal WT are delivered sequentially

to a maximum of four wiring workstations using compressed air.

Wires are requested on a project-specific basis by simply clicking on a button in the

“Eplan Smart Production”software tool. The assembled wire is available in a matter of seconds

and can be processed directly in the wiring project.

As well as substantial time savings, you also benefit from significantly enhanced quality with

consistent error minimisation.

Other benefits include:

Up to 90% time savings with wire supply

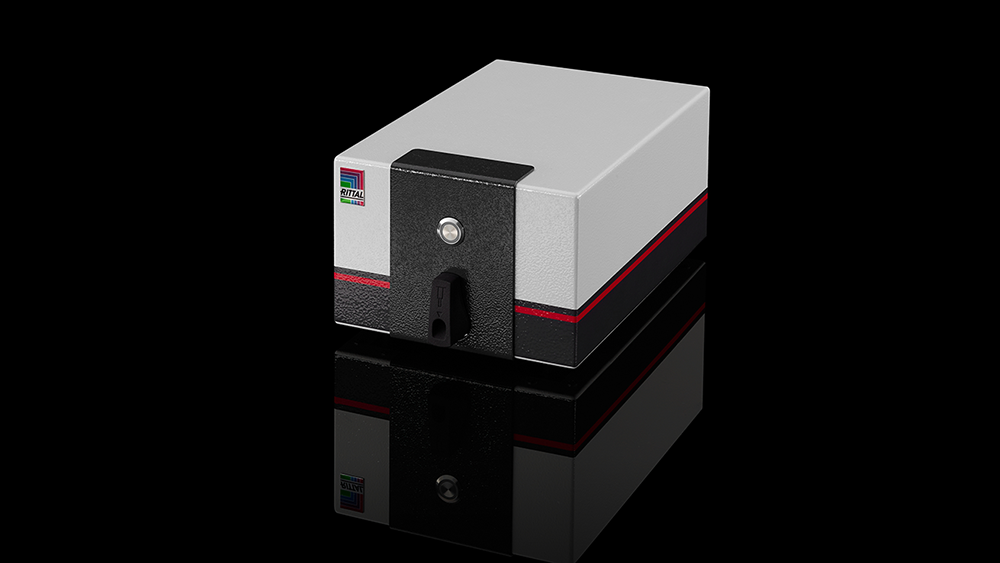

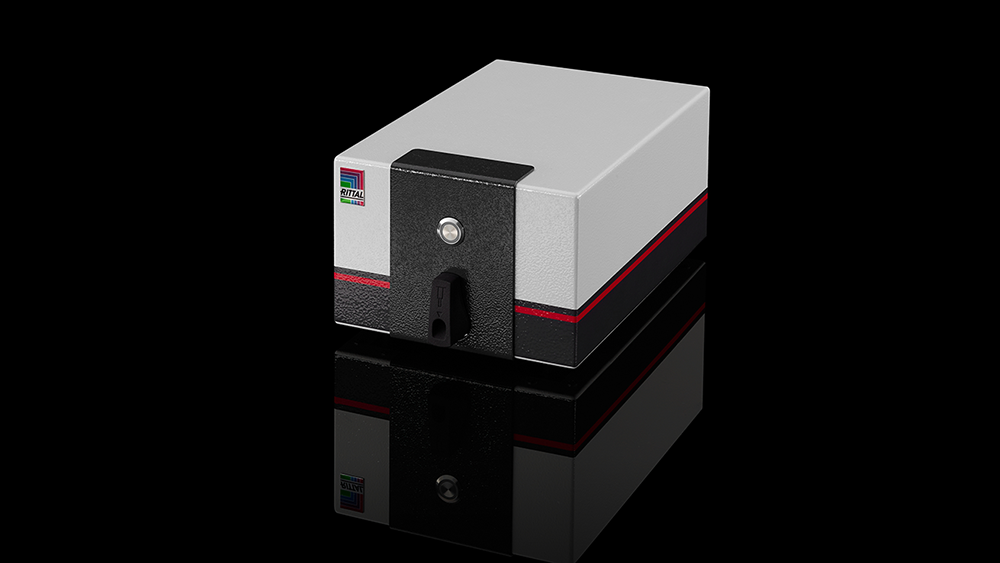

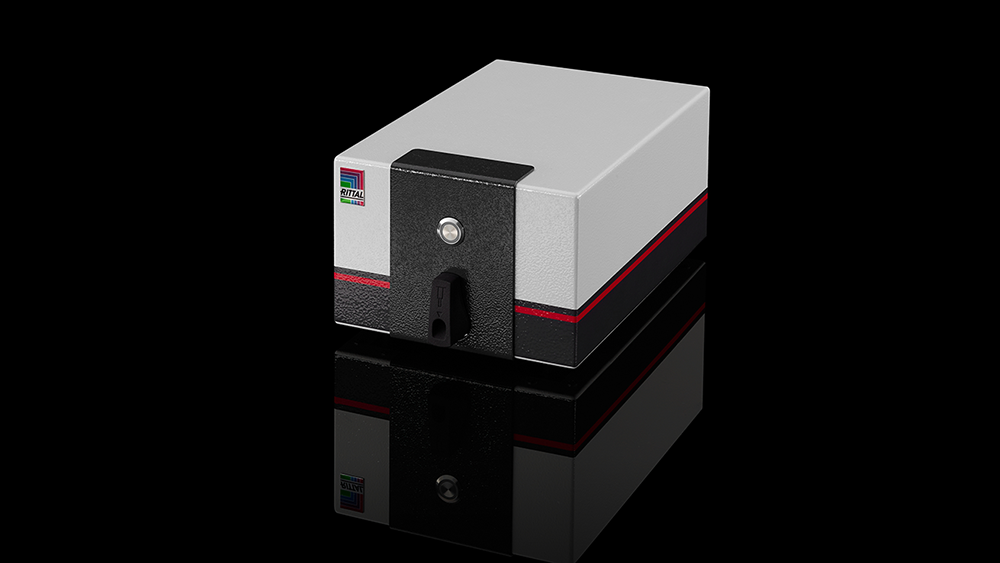

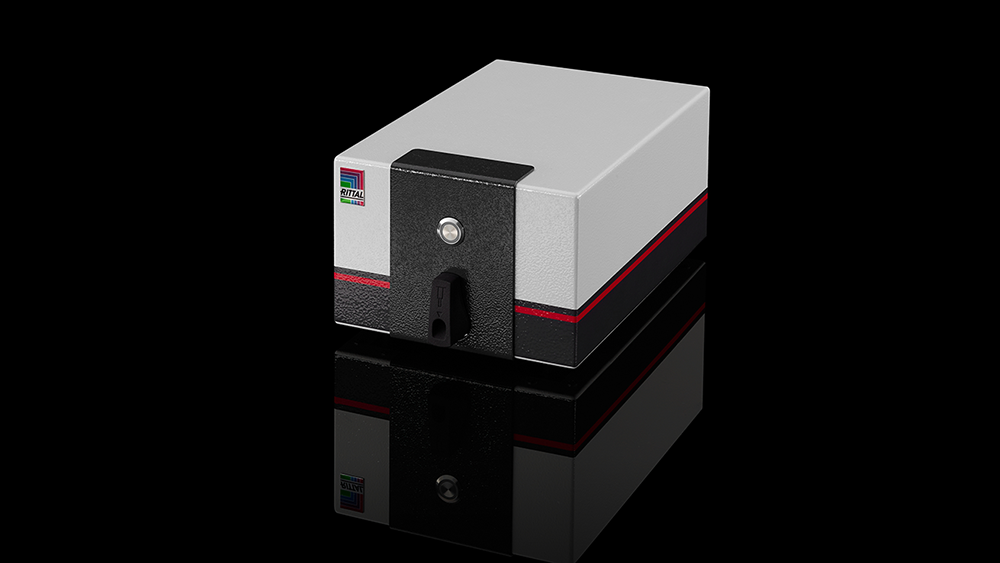

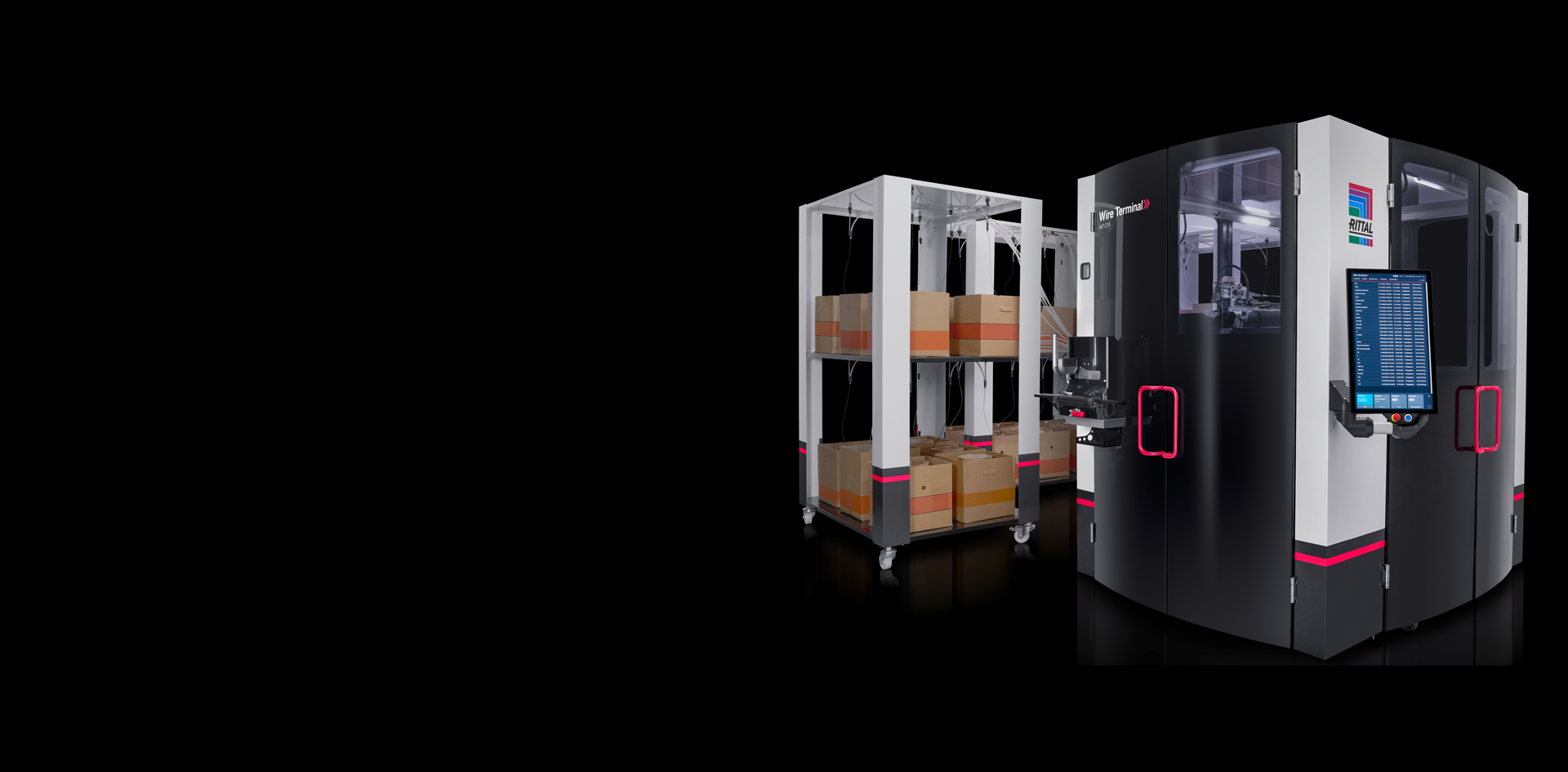

With the compact fully automatic wire processing machine Wire Terminal WT C, your wire assembly

becomes efficient and cost-effective. The fully automated process handles up to 36 different wires

with cross-sections from 0.5 mm² to 6 mm² without retooling. This includes cutting to length, infinitely

variable full and partial stripping, crimping of the wire end ferrules and labelling.

An optional printer unit enables the wires to be labelled in black, white or light-blue. The similarly

optional rail sorting system can accommodate up to 2,100 assembled wires. There is furthermore an

option to pass the wires to the downstream process steps as chain bundles.

The job management tool RiPanel Processing Center provides for consistent networking, from the

engineering stage to the production processes, with additional data import options, e.g. txt files.

All production data can be imported via interfaces and processed with the aid of EPLAN Smart Wiring.

Manual wire list specification is also possible.

Wire harnessing and processing in control engineering with machines, equipment and accessories from Rittal:

High-quality hand tools for professional industry and trade use.

These practical tools feature ergonomically styled handles for fatigue-free, non-slip working. Special tool-grade steel ensures a long service life and optimum protection against corrosion and means that it is really easy to crimp even cables with large cross-sections.

Accessories for manual and semi-automatic cable processing:

Reap the benefits from our range of accessories and consumables,e.g. for collaring wire end ferrules with plastic, certified to CSA-US and UL of course.

Our accessories may be used for manual wire processing and with Rittal crimping machines. The wire end ferrules are available to DIN and Rittal colour codes, heat-resistant to 105 °C, and suitable for all standard cables and special ferrules (AWG).

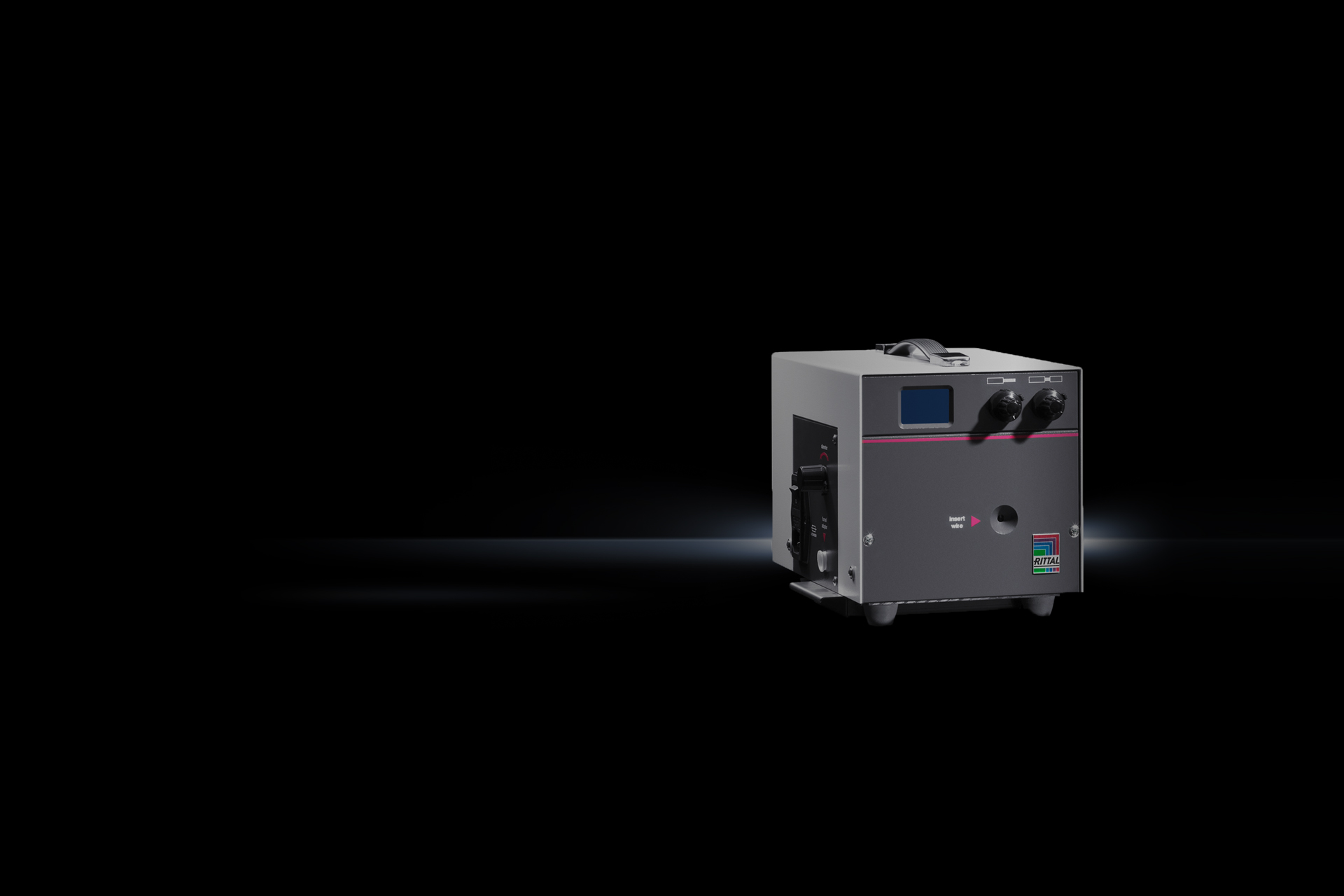

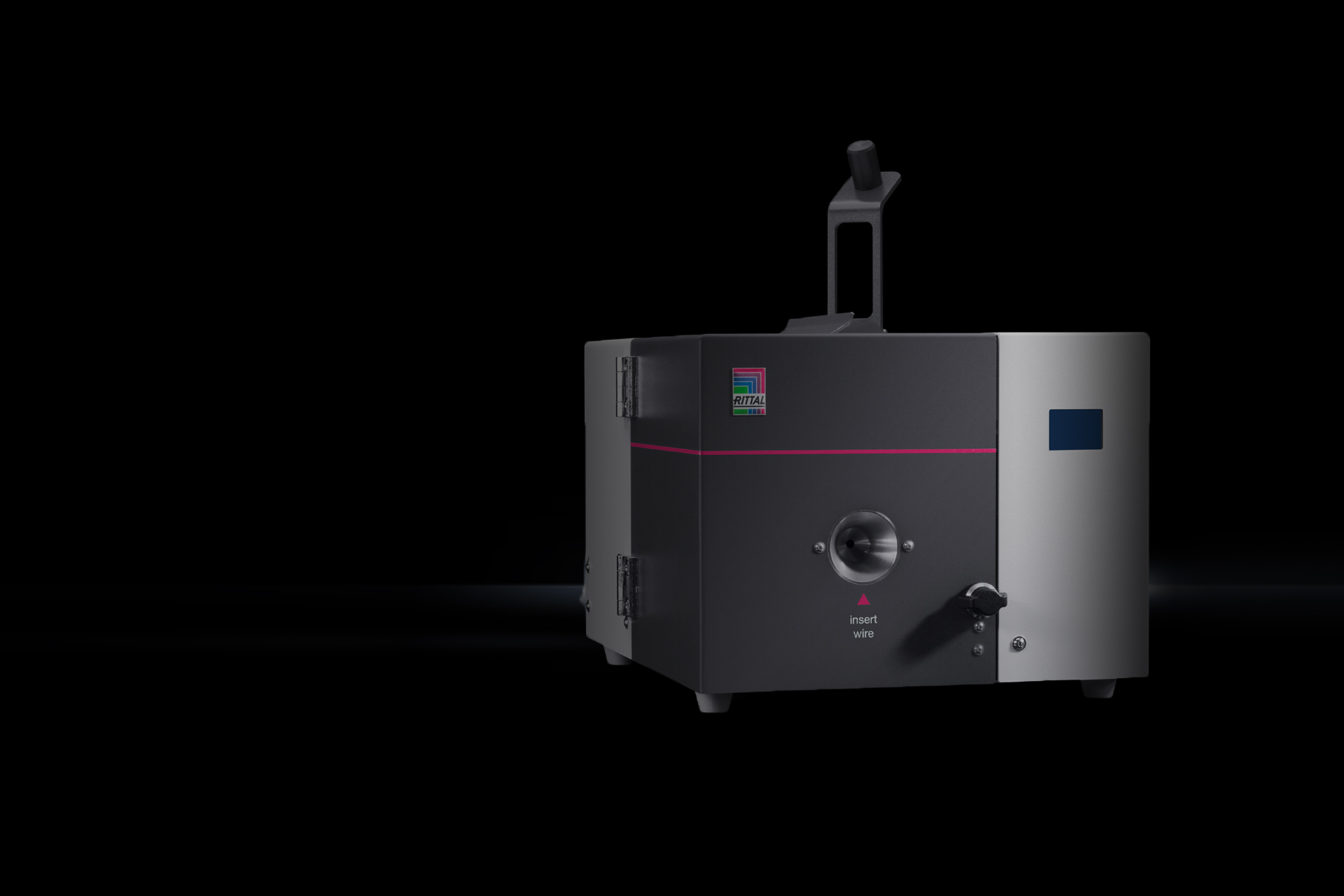

The C8+ length-cutting machine is sure to impress with its simple, reliable handling. Wires of up to 8 mm or 10 mm² diameter may be cut to an individually set length, for more efficient operating processes. This also guarantees excellent repetition accuracy thanks to the precise servo DC drive.

Cutting jobs can also be managed, documented and transmitted from your PC via a USB interface or via the CAE data interface (EPLAN Pro Panel). In this way, the C8+ length-cutting machine additionally supports the cable labelling and wiring of cables by displaying the relevant source/target code.

The electrically powered stripping machine S22 accurately and carefully strips the insulation from your wires. The stripping length can be easily controlled and adjusted accordingly.

The stripping machine also features a pre-integrated spare blade inside the enclosure. Other benefits include a running total counter and daily counter, which are easily read from the touch display.

The electro-pneumatic wire stripping and crimping centre L8 eliminates the need for tool changes. Linear adjustment of the blades and the high forces generated by the pneumatic crimping unit support the processing of standard cables as well as special ferrules.

Break even following investment in a crimping machine occurs after just 90,000 crimping operations!

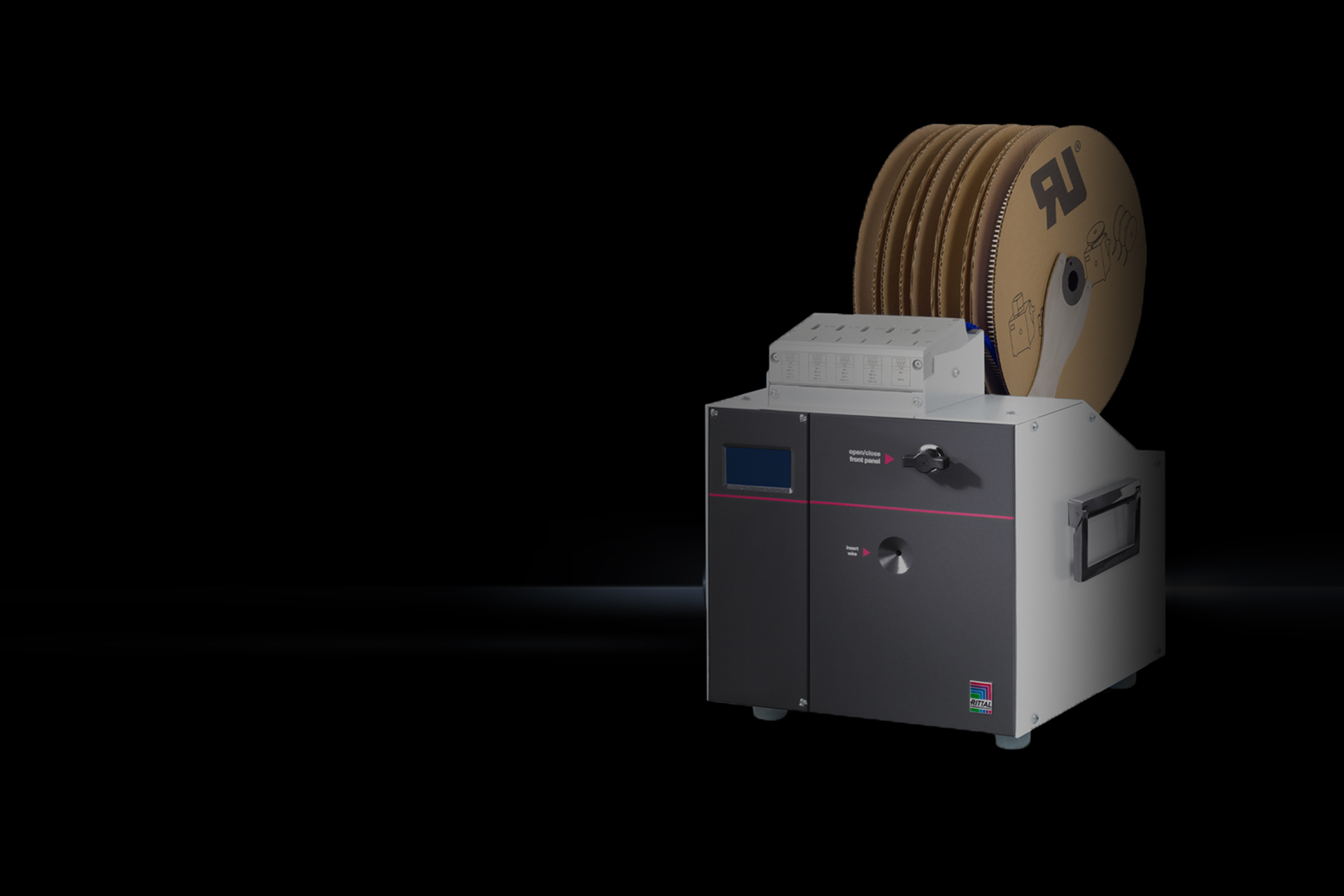

Electrically powered wire stripping and crimping machine for taped wire end ferrules on a reel. The R8 E crimping machine is ideal for fast, meticulous processing of insulated wire end ferrules and standard PVC cables in cross-sections ranging from 0.5 – 2.5 mm² (AWG 20 – 14) with a crimping length of 8 mm.

For flexible use in the workshop all you need is a power connection.

Break even following investment in a crimping machine occurs after just 90,000 crimping operations!

The RC stripping and crimping machine can be used for processing crimping lengths of 10 mm.

The integral 5-way holder allows the RC crimping machine to process five different cross-sections without retooling. This eliminates downtime and the associated set-up costs. The integral daily unit counter provides a continuous overview of your project quantities.

Break even following investment in a crimping machine occurs after just 90,000 crimping operations!

Rittal Automation Systems provide the finishing touches to the range, offering screwdrivers with and without insulation, bits and bit holders as precision-manufactured screwdrivers made from high-quality special tool-grade steel, and hex wrench sets with optimum hexagonal profiles and precise ball-head geometry.

Length-cutting, stripping, crimping and gripping tools:

Rittal Automation Systems offer solutions for processing ring terminals, wire end ferrules and crimp tab terminals and for stripping cables and wires, alongside cutting tools with long-term stable cutting performance and a variety of grippers, each with a suitable gripping surface.

Hydraulic punches for punching round, square and rectangular cut-outs:

Rittal Automation Systems offers a comprehensive range. Choose between manual hydraulic punches with 90° angled and 360° rotating cylinder head, electric hydraulic punches with high-performance drive motors and ergonomically styled handles, and hydraulic punches in a practical set with hole punches.

The products from Rittal Automation Systems will help you to automate your processes and accelerate throughput times. All enclosures, from the smallest to the largest, can be machined.

Our online Perforex ROI calculator lets you calculate your return on investment with the fully automated Perforex.

All from a single source – Rittal offers a comprehensive range of hand-held tools for professional support with your work operations.

Made from top-quality materials, our tools are exceptionally durable and their ergonomic structure and soft-touch handle sets them apart.

The tool adapts perfectly to your hand for fatigue-free working.

Got any questions? Please message us. We’ll be happy to answer all your queries about the Rittal Automation Systems.