Tested

Reduce unproductive periods and optimise your work processes with automatic tool control and tool length calibration for drill bits, thread cutters etc.

Production automation is the key to fast, reproducible processes of a consistently high quality. Even used as standalone solutions, Rittal’s equipment offers huge efficiency gains, from machining through to wire assembly.

Coordinating software solutions from Eplan are available as additional modules, for consistent, all-digital processes.

We can provide bespoke advice and flexible finance packages to help you find perfect-fit solutions and extend your process improvements to match your current and future situations, making you more efficient and competitive.

Discover our automation solutions and enjoy efficiency gains at every stage of the value chain.

Automate your machining processes and accelerate your throughput times with all enclosures, from the smallest to the largest.

Get to know our equipment to maximise your process potential.

Reduce unproductive periods and optimise your work processes with automatic tool control and tool length calibration for drill bits, thread cutters etc.

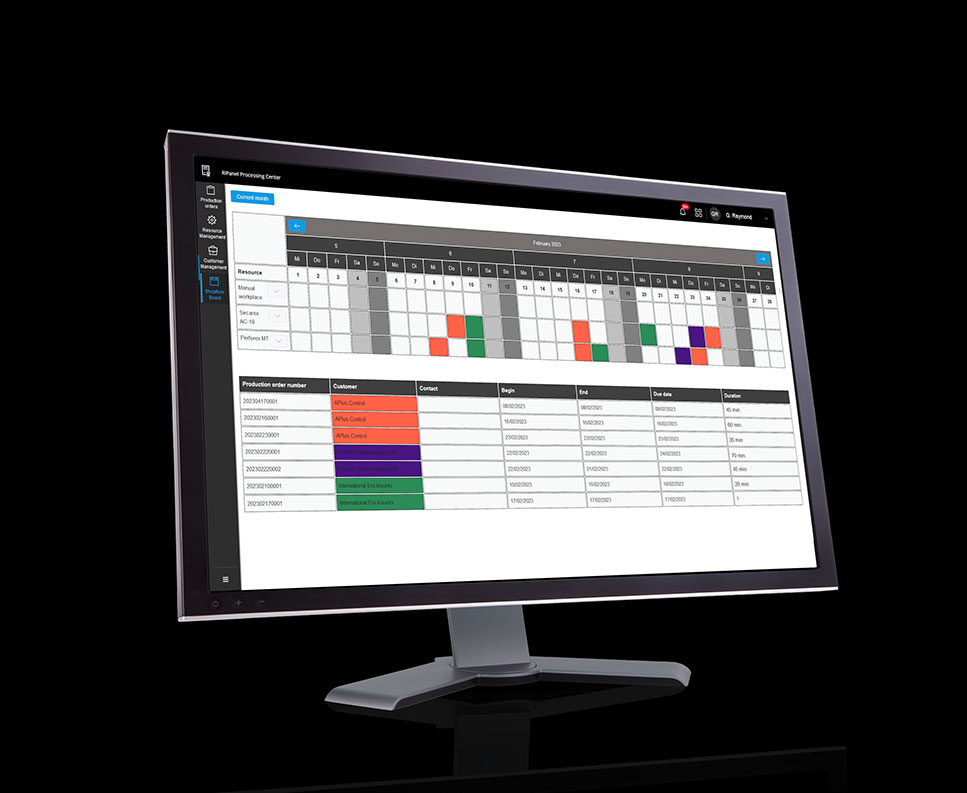

User-friendly operation thanks to the advanced and clear display of machine orders with guaranteed data continuity through network-based software.

Optional support arm for ergonomic machine operation.

Enclosure and flat-panel machining with pneumatic clamping – simple and secure.

High-performance spindle including minimum quantity lubrication for drilling, milling and thread tapping.

Superior swarf cleaning with optimised base sealing and integral swarf extraction in the spindle.

Reduced vibrations, faster feed rates and minimum noise levels ensure optimised machining.

Reduce unproductive periods and optimise your work processes with automatic tool control and tool length calibration for drill bits, thread cutters etc.

User-friendly operation thanks to the advanced and clear display of machine orders with guaranteed data continuity through network-based software.

Optional support arm for ergonomic machine operation.

Enclosure and flat-panel machining with pneumatic clamping – simple and secure.

High-performance spindle including minimum quantity lubrication for drilling, milling and thread tapping.

Superior swarf cleaning with optimised base sealing and integral swarf extraction in the spindle.

Reduced vibrations, faster feed rates and minimum noise levels ensure optimised machining.

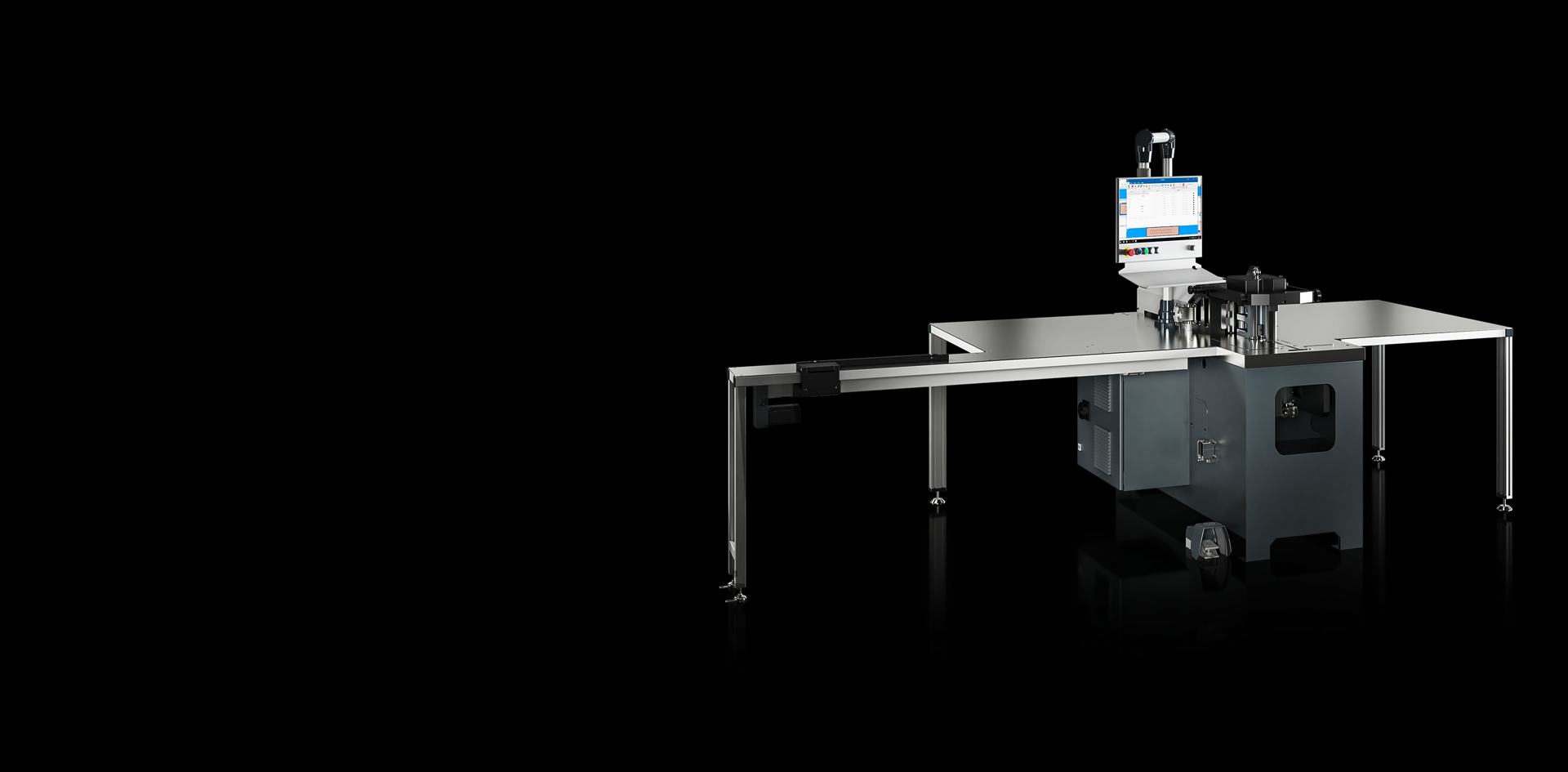

Perforex MT Milling Terminals will accelerate your throughput times when machining anything from the smallest cabinets and flat panels to your large enclosures.

The drilling and milling centres in the Perforex MT series can handle any machinable material, including spray-finished sheet and stainless steel as well as aluminium, copper and plastic.

A variety of CAD interfaces ensure problem-free data transfer from standard CAD systems and planning tools, such as .dxf, EPLAN Pro Panel, RiPanel Processing Center and Rittal Configuration System.

The machine pays for itself in next to no time and reduces throughput times even with a batch size of 1.

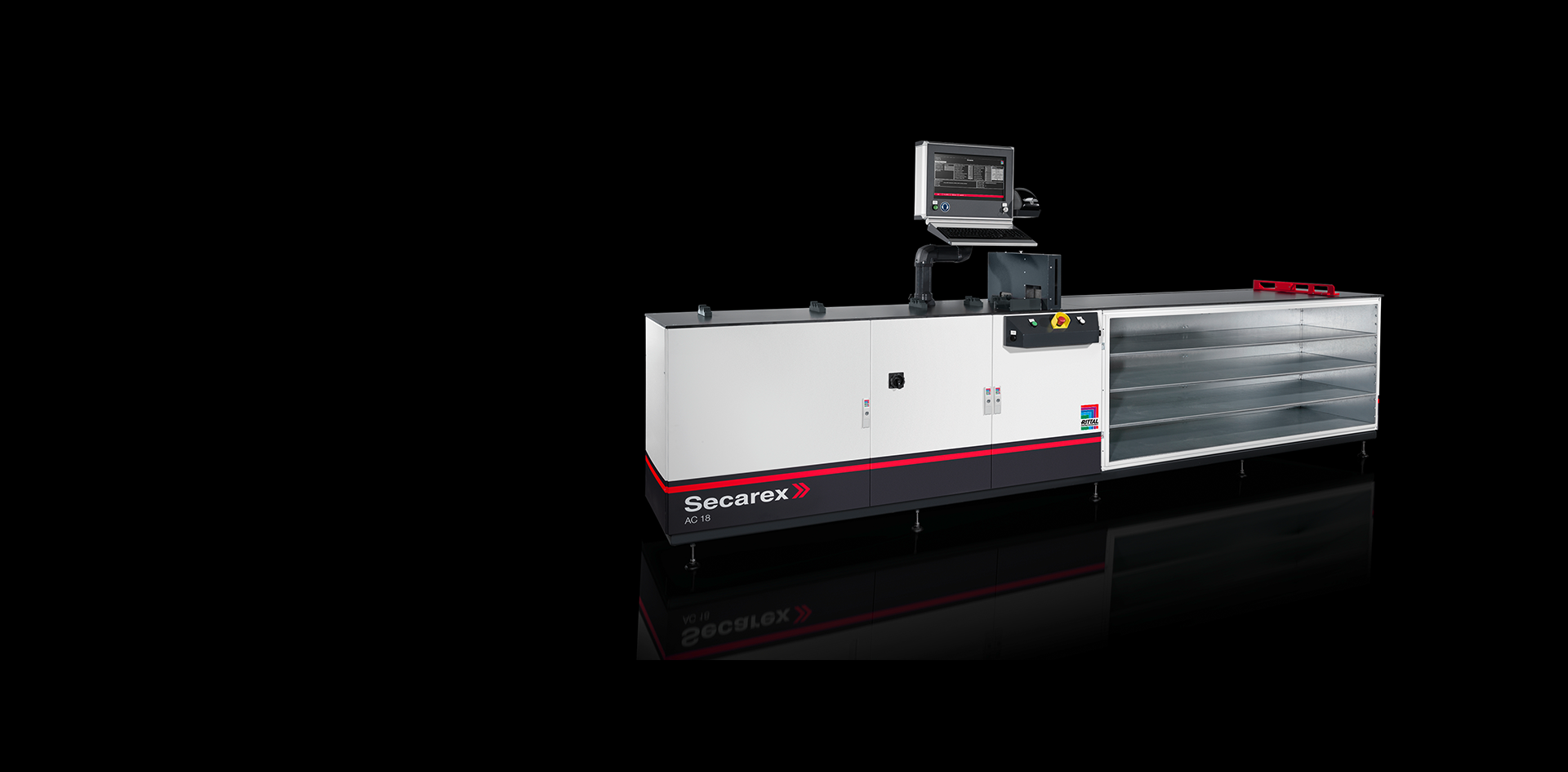

This image shows the full machine configuration.

Contactless, low-vibration manufacturing process:

Contactless, low-vibration manufacturing process:

The 3D laser technology used in the Perforex LC is ideal for machining stainless steel and sheet steel, as well as powder-coated metals such as enclosure doors, side panels etc. Spray-finished metal parts are cut without any visible paint damage or discolouration, even with delicate contours. What is more, there is no tarnishing of the cut edges when machining stainless steel.

The economic viability and cost effectiveness of the Perforex LC is achieved following a processing of approx. 150 stainless steel enclosures or 300 sheet steel enclosures per year.

The new RiPanel Processing Center from Rittal, in conjunction with EPLAN software, offers a seamless solution for the efficient management of production and machine orders. The production management tool ensures comprehensive process optimisation for complete planning confidence. Throughput times, errors and costs are significantly reduced.

Features:

How you benefit:

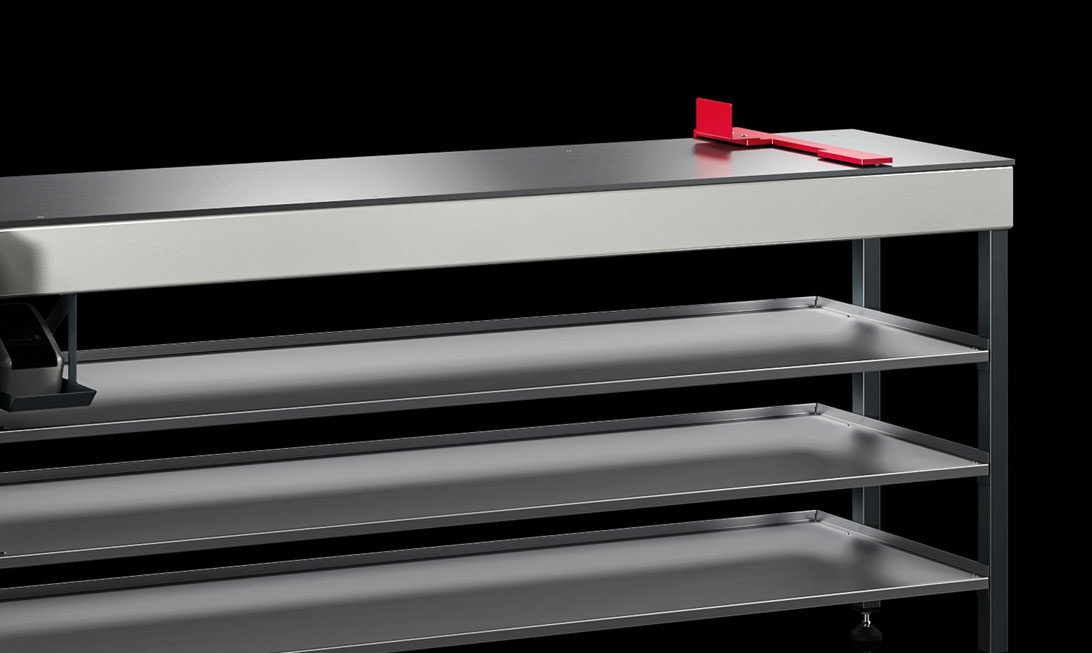

Optional storage system and drawer system for optimum storage of production documents and workpieces.

Direct view of the cutting process.

Optional storage system and drawer system for optimum storage of production documents and workpieces.

Direct view of the cutting process.

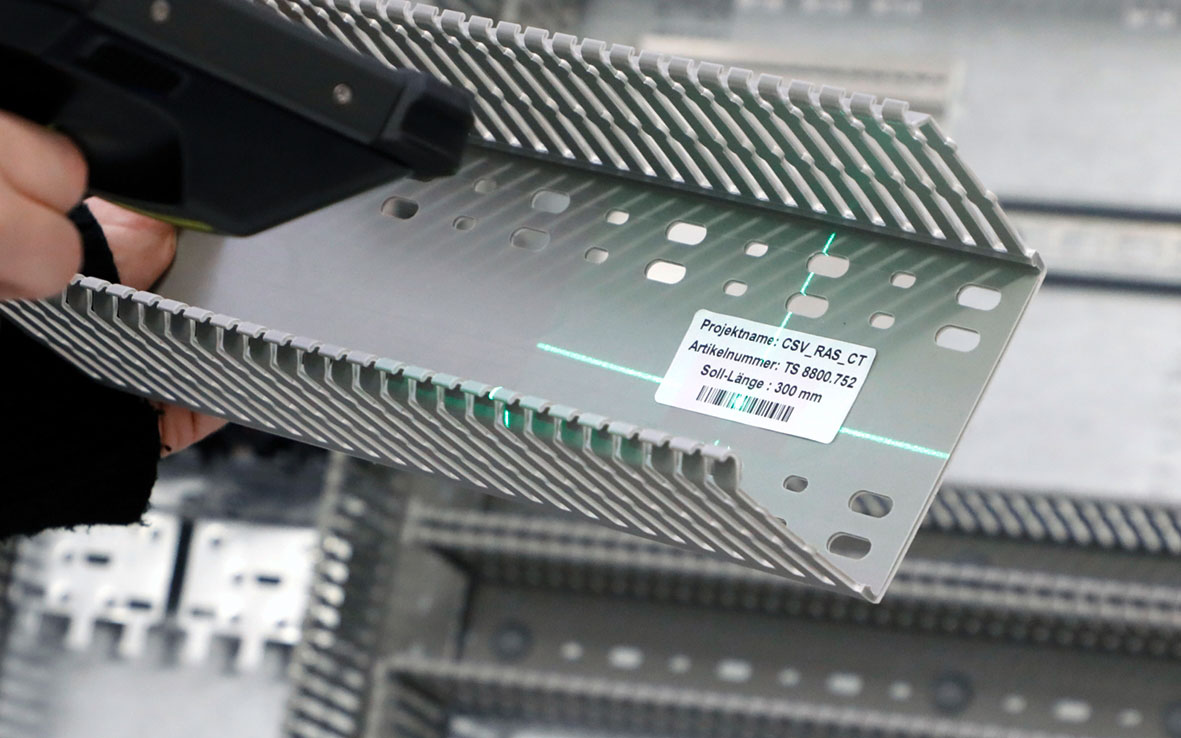

The Secarex cutting centre is easy to use and cuts wiring ducts, cable duct covers and support rails to length quickly, precisely and reliably. The integrated label printer provides project-specific labelling of the support rails and cable trunking.

The cutting centre helps to improve quality, reduce cutting waste, lower costs and accelerate the overall process.

The Secarex cost-effectiveness and economic viability is achieved after just 130 enclosures per annum.

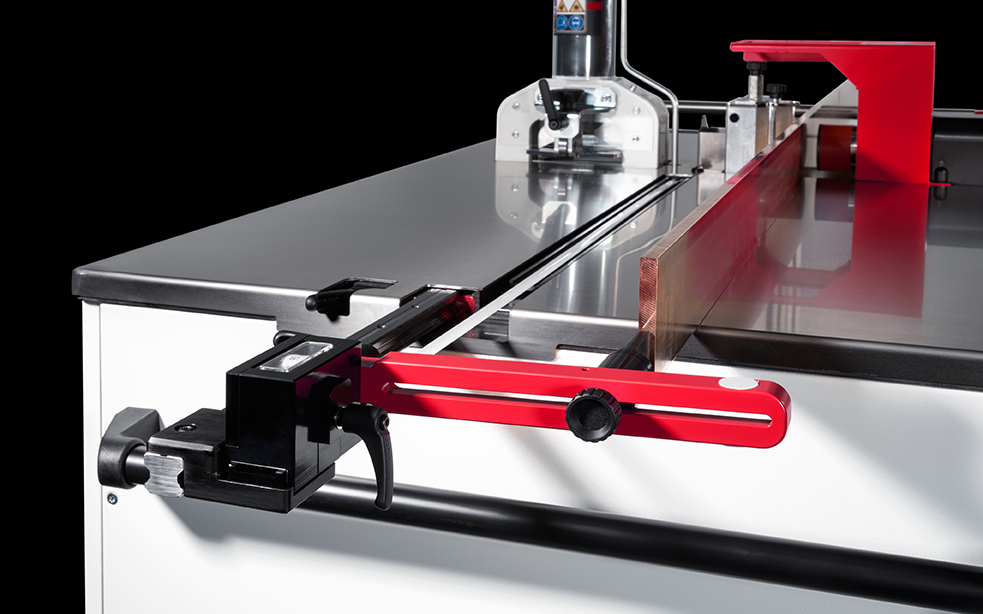

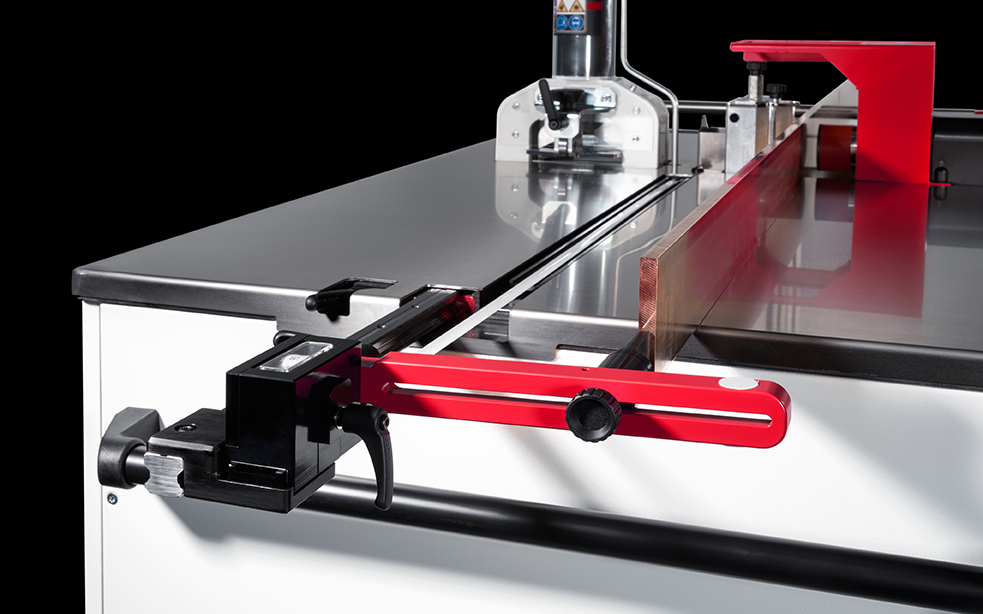

The integrated measuring unit also allows long busbars to be cut to the correct length.

Four large drawers provide plenty of space for storing all your tools and documents.

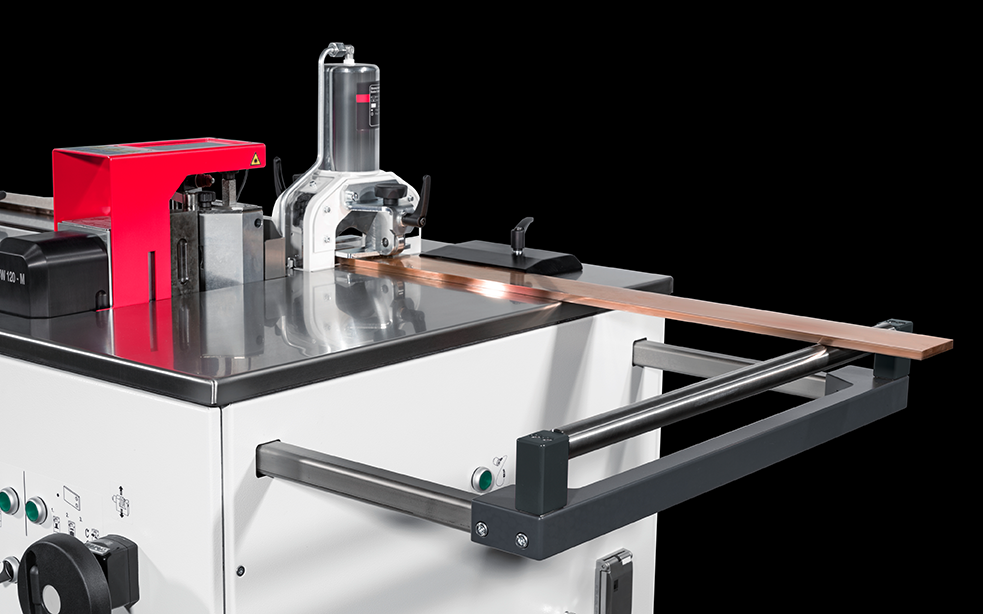

Pull-out side support extension for long copper bars.

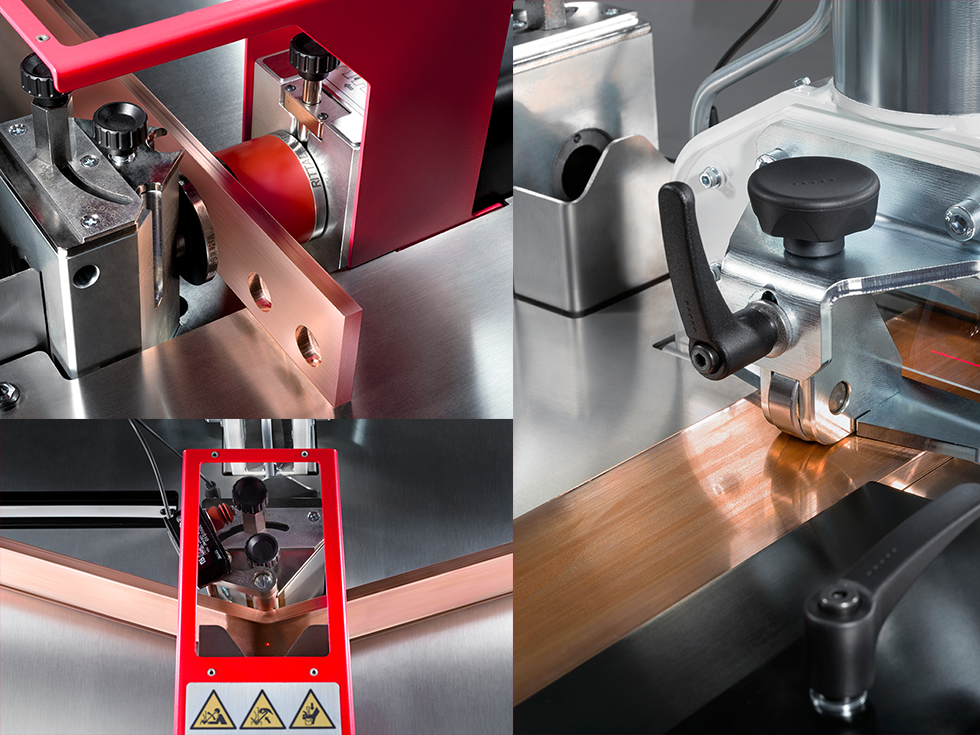

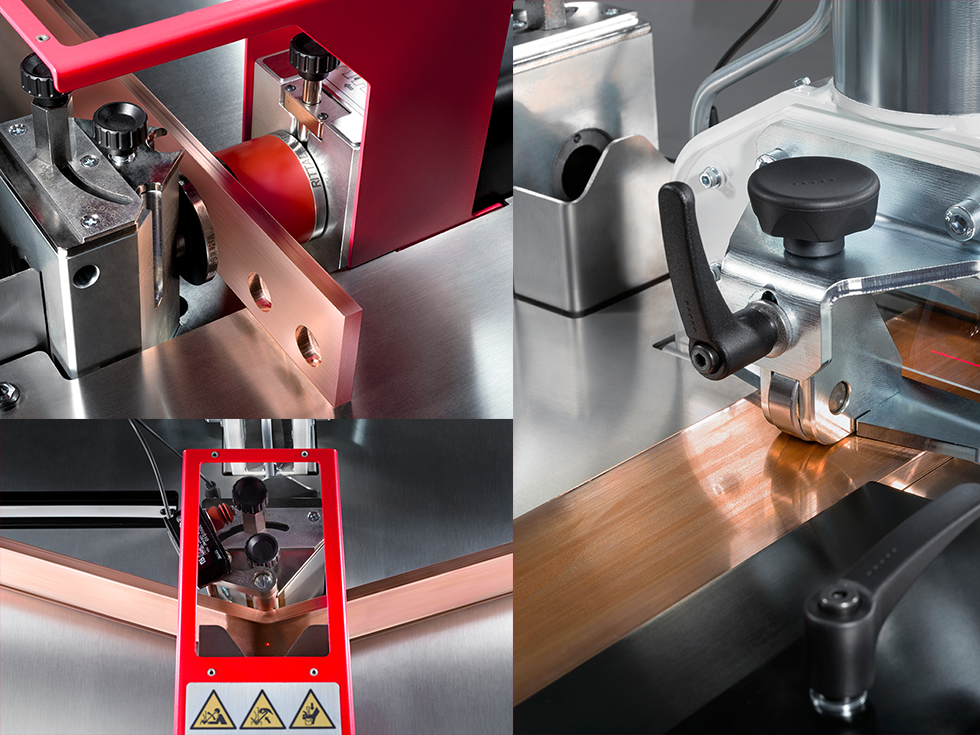

Integrated precision laser and electric L-blade for easier cutting and bending processes.

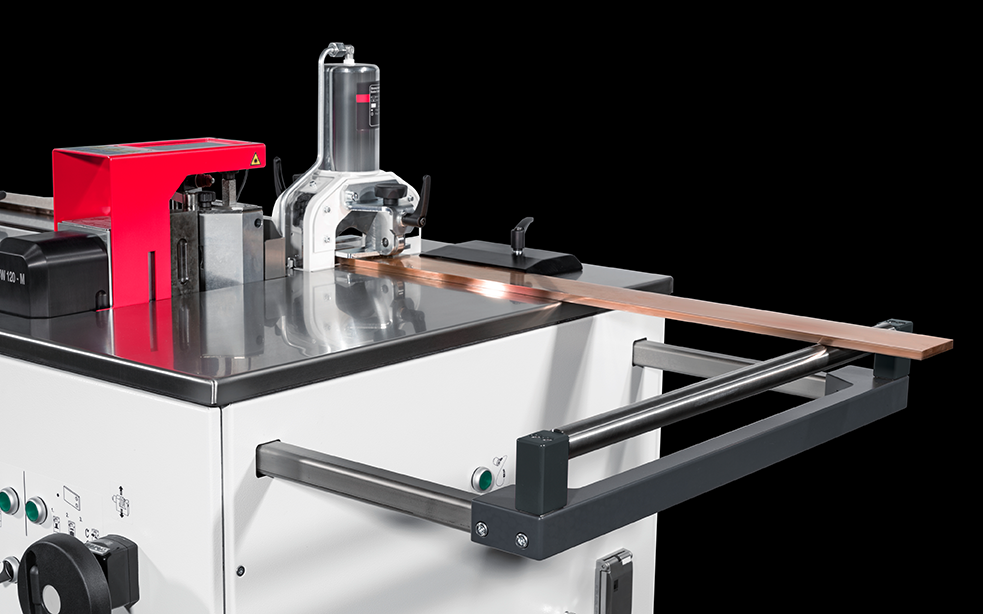

The Copper Workstation CW 120-M is ideal for bending, punching and cutting busbars.

The integrated measuring unit also allows long busbars to be cut to the correct length.

Four large drawers provide plenty of space for storing all your tools and documents.

Pull-out side support extension for long copper bars.

Integrated precision laser and electric L-blade for easier cutting and bending processes.

The Copper Workstation CW 120-M is ideal for bending, punching and cutting busbars.

The product solution for busbar machining is mobile and therefore ideal for precise, fast bending, punching and cutting of busbars directly at your workstation. This method of busbar machining is also far more efficient and ergonomic than manual processes.

The CW 120-M can also accommodate a range of optional accessories such as hydraulic cylinders and hole punches for machining sheet and stainless steel.

Busbar machining with fixed equipment is also possible.

The Punching Terminal PT S4 is an automation solution for machining busbars. Its bending centre is designed for fast, precise and flexible punching and length-cutting of flat copper bars.

How you benefit:

The Bending Terminal BT 20E is an automation solution for machining busbars. This electric bending machine supports a range of different bending types and boasts exceptional speed and precision.

Your benefit:

All from a single source – Rittal offers a comprehensive range of hand-held tools for professional support with your work operations.

Made from top-quality materials, our tools are exceptionally durable and their ergonomic structure and soft-touch handle sets them apart.

The tool adapts perfectly to your hand for fatigue-free working.

Got any questions? Please message us. We’ll be happy to answer all your queries about the Rittal Automation Systems.